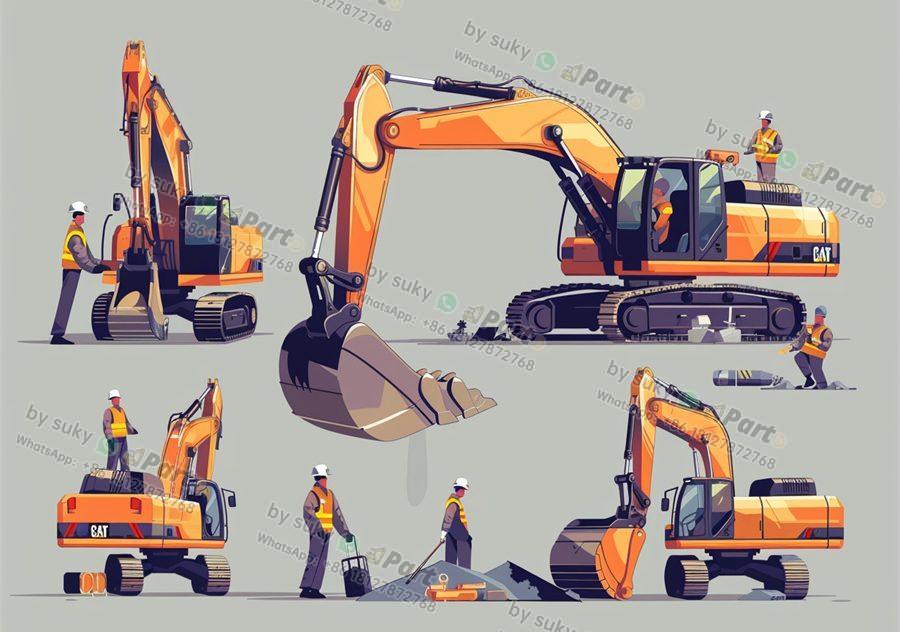

Excavator parts play a crucial role in the maintenance and repair of construction machinery. For importers and distributors in Christchurch, finding high-quality excavator parts is essential to keeping their machines running smoothly. In this article, we will explore the importance of excavator parts and how to find the best ones in Christchurch.

The Importance of High-Quality Excavator Parts

High-quality excavator parts are essential for the efficient operation of construction machinery. These parts are designed to withstand the rugged conditions of construction sites and ensure that the machines function at their best. By using genuine, high-quality excavator parts, importers and distributors can avoid costly repairs and downtime, ultimately saving time and money in the long run.

Where to Find Excavator Parts in Christchurch

For importers and distributors in Christchurch, finding a reliable supplier of excavator parts is crucial. There are several reputable suppliers in the area that offer a wide range of excavator parts for various makes and models of construction machinery. By working with a trusted supplier, importers and distributors can access high-quality parts that meet their specific needs and requirements.

Choosing the Right Excavator Parts Supplier

When selecting an excavator parts supplier in Christchurch, it is important to consider several factors. Firstly, importers and distributors should look for a supplier that offers a wide selection of parts from reputable brands. This ensures that they can find the right parts for their specific machines. Additionally, it is important to choose a supplier that provides excellent customer service and support to ensure a smooth purchasing experience.

In conclusion, finding high-quality excavator parts in Christchurch is essential for importers and distributors in the construction industry. By working with a reputable supplier and choosing genuine parts, they can ensure the efficient operation of their machinery and minimize downtime. Importers and distributors should prioritize quality when sourcing excavator parts, as it ultimately leads to cost savings and improved performance.